Timing is essential in product improvement. Corporations goal to introduce their ideas to the market to outshine rivals. A pivotal stage on this development includes crafting prototypes to authenticate and improve designs earlier than continuing with manufacturing. Conventional prototyping strategies could be sluggish and expensive.

There exists an answer: speedy prototype injection molding. This superior method presents a quicker and less expensive solution to create high-quality prototypes, enabling firms to check and iterate designs rapidly. This additionally accelerates new product improvement, saving firms time, sources, and cash.

What’s Fast Prototype Injection Molding?

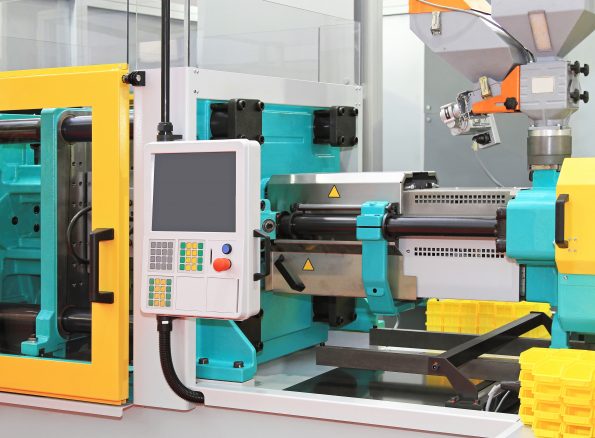

Fast prototype injection molding is a technique that empowers designers and engineers to manufacture top-notch prototypes quickly and cost-effectively. It entails using a mildew sometimes crafted from aluminum or metal to duplicate a component or product design utilizing an injection molding machine. The mildew is full of a thermoplastic polymer like ABS or polypropylene, which then solidifies to create the specified type.

Benefits of Fast Prototype Injection Molding

1. Swiftness

The time it takes for a product to succeed in the market can decide its success, and one notable advantage of speedy prototype injection molding lies in its pace. Not like strategies that may necessitate weeks and even months, this method yields elements inside days, generally even hours.

2. Value Effectivity

One important benefit is the fee financial savings facet. Not like manufacturing strategies that necessitate pricey tooling earlier than manufacturing can start, speedy prototype injection molding considerably reduces these bills through the use of 3D-printed molds or reasonably priced aluminum instruments for small manufacturing batches.

3. Flexibility in Iterations

Fast prototype injection molding offers flexibility all through the design iteration course of. Being comparatively budget-friendly in comparison with alternate options, companies can create iterations of their prototypes with out overspending. This flexibility permits for performance and match testing, making certain improved end-product efficiency.

4. Testing Feasibility in Manufacturing

By implementing prototype injection molding strategies early on within the product improvement section, companies have the possibility to evaluate the manufacturability and efficiency of their designs. This method permits them to proactively establish and rectify manufacturing challenges or design flaws, finally resulting in high quality ultimate merchandise.

Deciding on the Acceptable Materials

The fabric selection in prototype injection molding performs a task in maximizing the advantages of this method. Designers have quite a lot of choices, together with thermoplastic polymers like ABS, polypropylene, polystyrene, and nylon.

When deciding on a cloth to your prototype, components comparable to energy necessities, sturdiness, temperature resistance, flexibility, and floor end must be considered.

Having a dialogue about these traits together with your prototyping companion can help you in figuring out the fabric to your specific utility.

Collaborating with a Prototype Manufacturing Accomplice;

To totally make the most of the benefits of prototype injection molding, it’s essential to work with a good and skilled prototype manufacturing companion. Hunt down an organization with experience throughout industries and a confirmed monitor document of delivering top-quality prototypes inside timelines.

By having the companion by your facet, you may leverage their data and expertise all through the challenge’s lifecycle. They are going to help you in designing molding options whereas making certain communication between your workforce and theirs. Common updates throughout the course of will hold everybody knowledgeable concerning the progress made and challenges confronted.

Unleashing Innovation Potential

Fast prototype injection molding expedites product improvement by accelerating iterations and lowering prices in comparison with strategies. Investing on this method permits companies in sectors to grab alternatives and keep forward of rivals swiftly.

Concluding Ideas

In right now’s surroundings, pace to market is essential. Fast prototype injection molding empowers companies to hasten product improvement by minimizing time to market by way of turnarounds whereas managing bills successfully.

To take advantage of expertise’s benefits, it’s essential to decide on supplies tailor-made to every use and collaborate with expert prototype makers who’re well-versed in business requirements. Incorporating speedy prototype injection molding will help you attain your product improvement goals precisely. Keep on the forefront, improve your design testing course of, and unleash your creativity by embracing this groundbreaking technique.